How to Choose the Right Stainless Steel Woven Wire Mesh?

Choosing the right stainless steel woven wire mesh is crucial for various industries. According to a recent market report, the demand for stainless steel woven wire mesh is expected to grow by 5% annually. This growth reflects its importance in sectors like food processing, petrochemicals, and construction.

Experts emphasize the significance of selecting the appropriate mesh type. John Smith, a leading expert in wire mesh technology, stated, “The right stainless steel woven wire mesh can enhance product quality and operational efficiency.” His insights underline the mesh’s role in ensuring durability and resistance to corrosion.

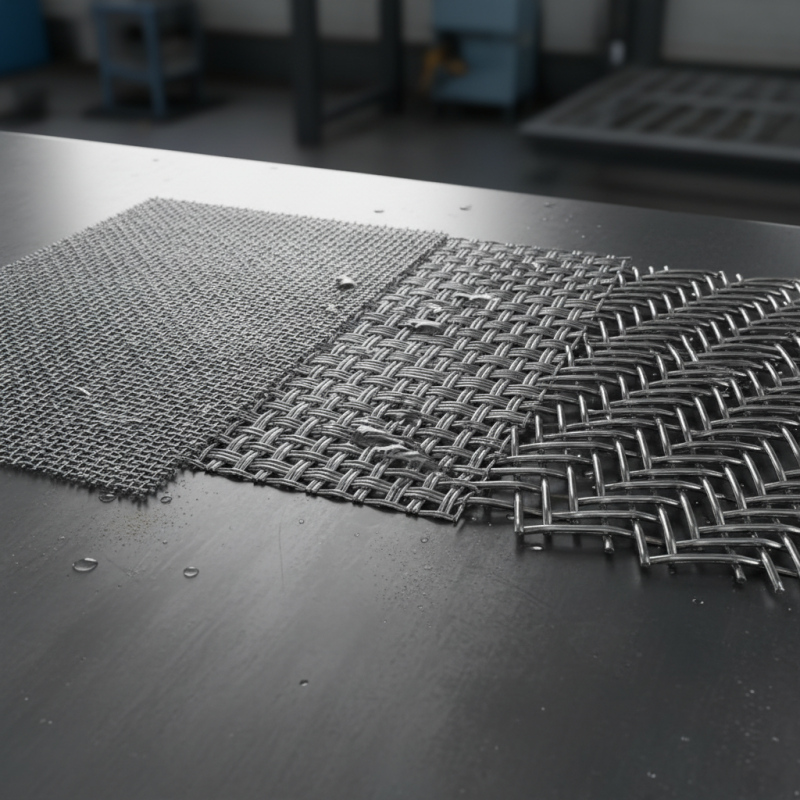

Making a choice can be overwhelming. Different weave patterns and wire diameters affect performance. For example, a fine mesh offers filtration, while a coarser mesh provides support in construction. Recognizing these characteristics is essential but often neglected. A thoughtful selection process is necessary for optimal results.

Understanding the Basics of Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh is a versatile material used in many industries. Understanding the basics is crucial for selecting the right type. Stainless steel offers excellent corrosion resistance. This makes it suitable for both indoor and outdoor applications. According to industry reports, over 50% of stainless steel mesh is utilized in construction. It’s favored for its durability and strength.

Different types of stainless steel exist. The most common are 304 and 316 grades. Grade 316 excels in environments with higher exposure to saltwater, making it ideal for marine applications. However, it tends to be pricier than 304. A report by the International Stainless Steel Forum indicates that choosing the wrong grade can lead to premature failure or costly replacements.

Mesh size is another critical factor. A smaller mesh size can filter finer particles but may block airflow. Conversely, a larger mesh allows better ventilation but may compromise filtration. It's crucial to balance these needs based on the intended application. Selecting the right stainless steel woven wire mesh involves careful consideration of these factors. Taking the time to evaluate specific requirements can prevent costly mistakes down the line.

How to Choose the Right Stainless Steel Woven Wire Mesh? - Understanding the Basics of Stainless Steel Woven Wire Mesh

| Mesh Type | Wire Diameter (mm) | Open Area (%) | Applications | Corrosion Resistance |

|---|---|---|---|---|

| Plain Weave | 0.5 - 2.0 | 30 - 40 | Filtration, Sieving | High |

| Twill Weave | 0.5 - 3.0 | 20 - 35 | Chemical Processing, Food Industry | Very High |

| Dutch Weave | 0.2 - 1.5 | 10 - 25 | Filtration, Water Treatment | Moderate |

| Leno Weave | 0.4 - 2.5 | 25 - 45 | Agricultural, Construction | High |

Identifying Different Types of Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh comes in various types, each serving specific purposes. Key types include plain Dutch weave, twilled weave, and single reinforced mesh. The plain Dutch weave is strong, making it ideal for filtration applications. Interestingly, twilled weave offers flexibility while maintaining strength, suited for both industrial and architectural uses.

When selecting the appropriate mesh, consider the wire diameter and the aperture size. Data shows that a smaller aperture ensures finer filtration, while a thicker wire enhances durability. This balance is essential for applications needing both strength and precision.

Tips: Always check the specifications. Understand the environment where the mesh will be utilized. For outdoor use, corrosion resistance is crucial. Additionally, think about how the mesh will be cleaned and maintained. Finding the right mesh can be trial and error. Manufacturers often underestimate the importance of mesh selection. Monitor performance and be ready to adjust accordingly.

Evaluating Wire Gauge and Mesh Size for Your Needs

Choosing the right stainless steel woven wire mesh involves understanding both wire gauge and mesh size. Wire gauge refers to the thickness of the wire used in the mesh. A lower gauge number indicates a thicker wire. For example, a 10-gauge wire is approximately 0.102 inches thick, while a 30-gauge wire is only 0.010 inches. The right gauge impacts the mesh's strength and durability.

Mesh size indicates the number of openings per linear inch. Smaller mesh sizes, like 80 mesh, have more openings, but they can reduce overall flow and increase resistance. This is crucial in applications like filtration. Research shows that many industries prefer mesh sizes between 10 and 60 for optimal balance. However, fine mesh, while effective for filtering, may clog quickly and necessitate frequent replacements. This can lead to higher maintenance costs.

Consider the specific needs of your project. Evaluate what you need. If you require high strength, opt for a lower gauge. Alternatively, if your priority is fine filtration, a higher mesh size may be ideal. Each choice presents trade-offs. Perfect solutions rarely exist. Always factor in your budget and operational requirements.

Assessing Corrosion Resistance and Durability Factors

When choosing stainless steel woven wire mesh, assessing corrosion resistance is critical. Different environments affect the material differently. For instance, coastal areas expose mesh to saltwater, which accelerates corrosion. Therefore, selecting high-quality stainless steel is paramount.

Durability factors also play a significant role. Some types of woven wire mesh can withstand heavy loads, while others may not. Consider the specific application. A mesh used for filtration needs to endure constant pressure, leading to potential wear and tear. Always evaluate the weave pattern too. Some patterns offer greater strength, while others may compromise it.

Visualizing how the mesh fits into your project makes a difference. Picture the conditions it will encounter. Will it face high humidity? Or will it be shielded from direct exposure? Reflection on these details can help prevent future failures and ensure the right choice. It's easy to overlook these aspects, but doing so could lead to costly mistakes.

Considering Applications and Industry Standards for Selection

Choosing the right stainless steel woven wire mesh requires a thorough understanding of its applications and industry standards. Each industry has specific needs. For example, food processing requires materials that meet sanitary standards. A mesh that works well in one sector may not be suitable for another.

It's essential to consider the mesh's specifications. Identify the desired opening size and wire diameter. These factors significantly impact the material's strength and filtration capabilities. Too large an opening may lead to ineffective filtering. Inadequate wire thickness may compromise durability.

Many professionals overlook the environment where the mesh will be used. Corrosive substances can damage materials not suited for such conditions. Testing is crucial before final selection. Consider dividing tests into different scenarios. Each reflects real-world use better than single tests. These reflections can guide a more informed decision.